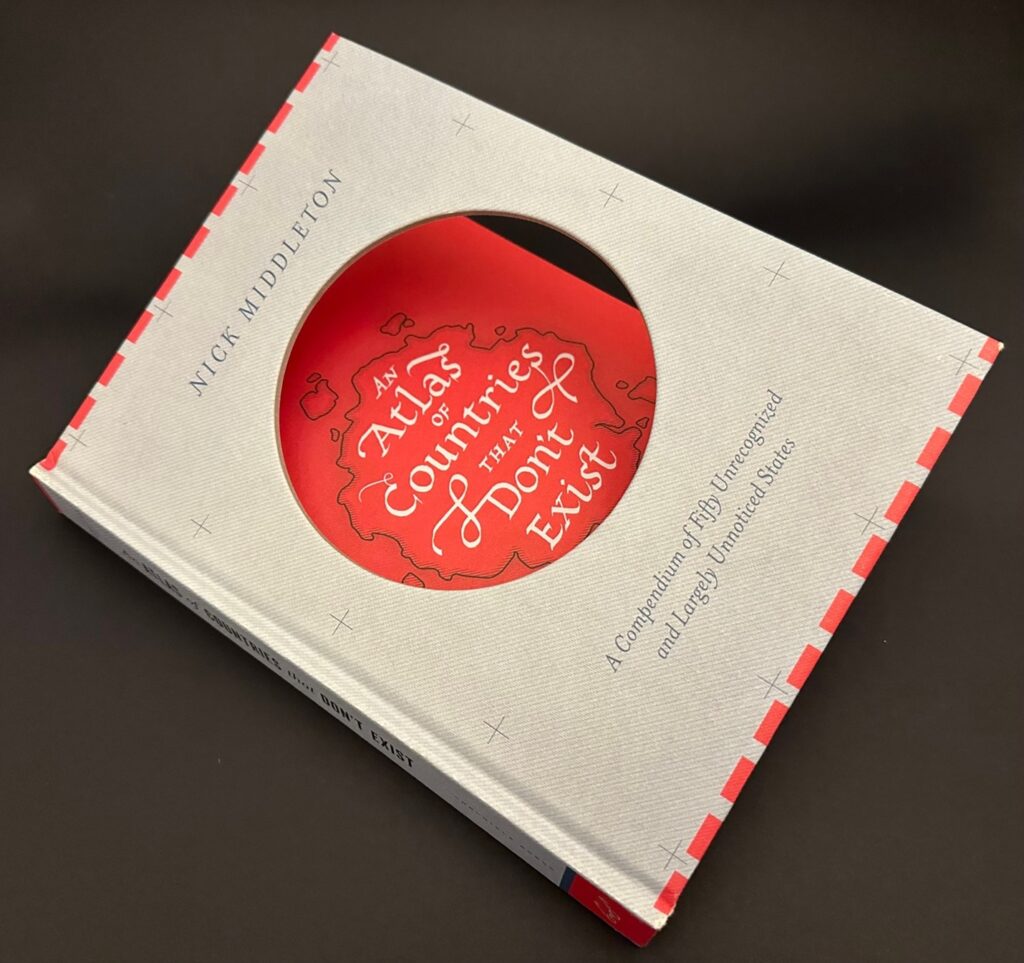

This is another example of a die cut cover for a hardback case bound book. This particular one you can see is a perfectly round circle. Could be jagged, could be multiple shapes. In this incident the cover was unwrapped. Whether the cover is unwrapped or wrapped, it makes no difference. If you want something die cut like this case bound hardback book we can help. We have one specialized machine that actually does die cutting on hardback bound books.

Another distinctive, hardback case bound book with coloured headbands and printed endpapers. The obvious is a die cut front cover. We could die cut a circle up to 8 1/2 inches wide or larger, if the book was much larger. The die-cut can be oval, triangle shaped, or jagged edge. I’ve seen situations with two die-cut holes in the hardback case. One additional process that we can perform is die-cutting the chipboard interior of the case, off-line die, cutting the cover with a smaller circle with slits in it. When we produce the cases automatically and then the slit flaps are glued around the edges of the hole in this situation you can’t see the gray chipboard inside the die-cut hole. It would be the same colour as the printed cover wrap. More expensive, more appealing and obviously more distinctive and functional.

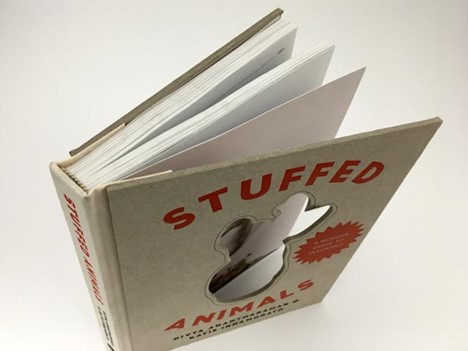

This hardback case bound book is the largest die-cut hole size of any book I’ve ever seen. Our clicker die-cutting machine cut the holes in the cover. There could be one or two or three hole shaped, as ovals, squares, triangles or circles. Usually when you see a hardback case bound book with a die-cut cover similar to this, instead of having a picture printed on the front cover as you can see here it’s on the inside of the end paper. When we die-cut the cover we bind the book in a normal style. We open the cover 180 degree and die-cut. When we’re die-cutting what we’re doing is cutting through the actual cover mounted to the next panel of the endpaper. 99.9% of all endpapers are blank but in this case, they must be printed.

Who can die cut extra thick book covers? We can!

Who can die cut extra thick book covers? We can!

In this video, I highlight our expertise in die-cutting window designs on thick book covers. Most book covers are made with 100pt board, but sometimes clients want something thicker!

Die cutting intricate designs on lightweight stock is straightforward, but very difficult with a thick board. We excel at creating custom designs on hardback books, even with the most challenging requirements.

On many occasions, printers from across North America tell us that we were the only bindery they found that could do their entire job. We do it all – from 1) die cutting an intricate design on thick book covers; 2) Smyth sewing or perfect binding; and 3) book case making.

Our die-cutting services extend beyond just covers. We can create die cuts on dust jackets and interior pages, providing endless opportunities to make your book truly special.

Trade Die Cutting for Book Covers!

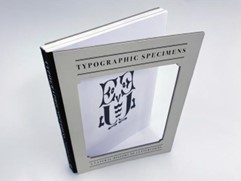

Trade die cutting isn’t just for tags, packaging, folders, stickers, etc. It also makes a great addition to books – for soft cover books, exposed chipboard covers and interior pages!

Die Cutting a book cover turns a simple piece into a work of art. A windowed book cover allows the reader to see inside a section of the cover. We can cut a decorative shape relevant to the book’s topic or product being promoted – the choice is yours.

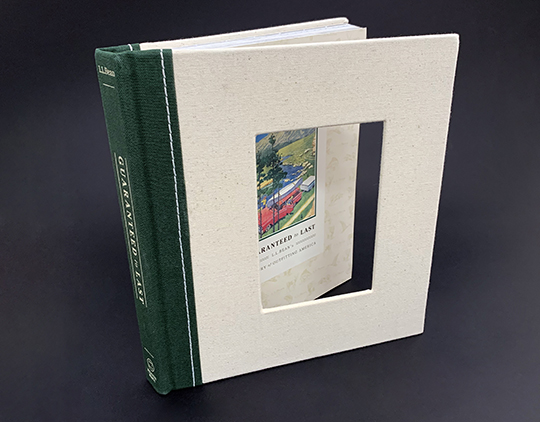

The book I’m featuring this week has a die cut windowed cover that is also case wrapped! First, the chipboard cover material has a window die cut. Then, the cover was mounted to the fabric, with special care taken to wrap the inside of each of the window sides.

The image above shows how the inside cover liner hides the fabric edges that have been folded over the die cut window edges.