SIDE SEWING

Another method of binding the pages of a hard back book is called side-sewing with thread. We intentionally apply the thread very close to the binding edge of the spine. This particular process is very environmentally, friendly and, Iies reasonably flat.

When the book is “opened” the user can see the thread, which in the situation of wire, saddle, stitching, or box ditching, you can’t see how was bound when you open the page is up.

SIDE SEWING

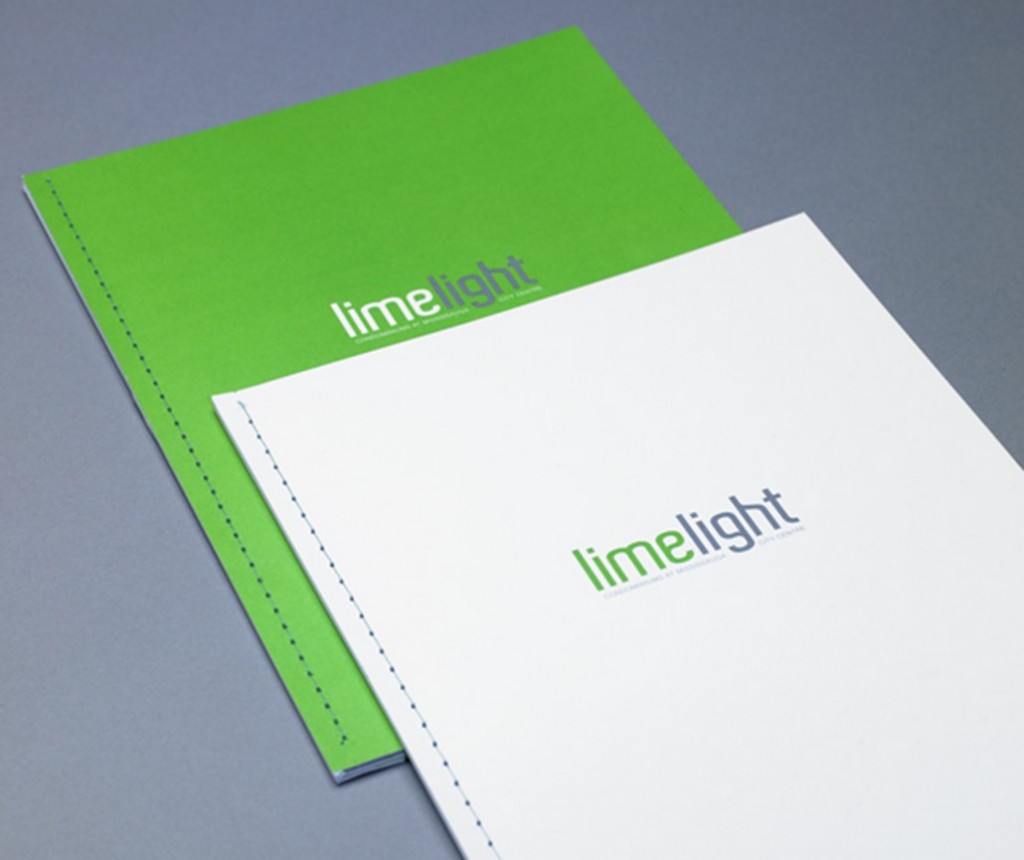

This is a collage of a number of books that are side sewn. This environmentally friendly method of taking single sheets and casing them into a hardback book cover; environmentally, friendly, very durable. Negatives are they don’t lay flat. Side sewing is much more costly than perfect binding. However, if you have a single sheet book, you want bounded the most environmentally, friendly way possible, more durable than perfect binding side sewing might be the answer.

Side Sewing

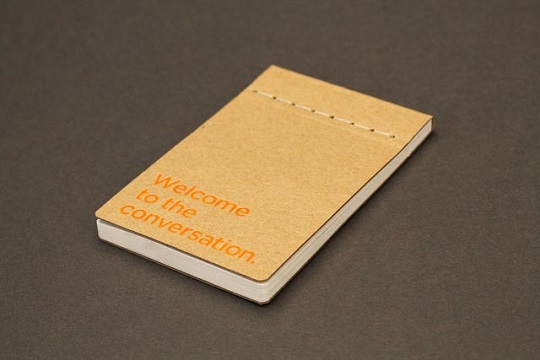

We have responded to market demands and we have added 5 new improvements and, in addition, solved a problem!

The image show a Side Sewn book that is 1) thicker than we could produce before and 2) we can now us a heavier, stronger, thicker thread than before.

The red book shown illustrates our best improvement in Side Sewing. Traditionally, Side Sewing looked great on the front cover but was pretty ragged looking on the back. This book has NO ragged stitches on the back cover!

This next image is the first piece we have in this style. When closed, you see no line of thread, but when opened, you see two lines of different coloured thread. There is also no thread showing on the back cover. This is a new style and new idea!

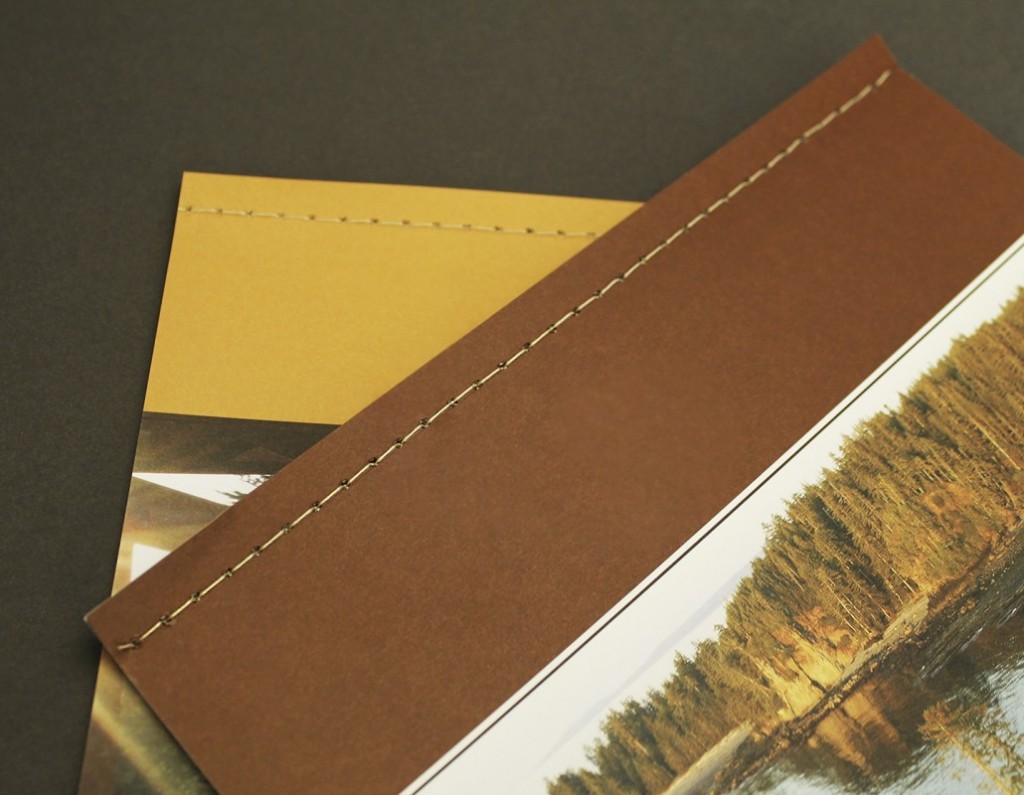

The following two images illustrate a slightly different Side Sewing stitching pattern.

These next two images illustrate a new sewing style called the Zig-Zag. Two benefits of this style are 1) a great aesthetic and 2) a slightly stronger binding style.

The white book shown below is different than the others in that the thread only goes through the front cover – not the entire book. When opened, the book is actually perfect bound! The thread on the cover is for entirely aesthetic purposes, not functional.

This last image illustrates the problem we solved! The client need a perfect bound styled book, but couldn’t use perfect binding because the hot-melt glue required is technically non-recyclable. Our solution was to Side Sew the pages and then cold glue the last page onto the inside of a heaver cover. The thread is pure cotton and the cold glue (which is not strong enough to use in perfect binding) is 100% recyclable. Problem solved! We’ve now produced this job twice and we see a growing need for 100% recyclable binding methods like Side Sewing.

Features

Multiple colours of thread

Multiple lines of thread

Tactile binding method – raised stitches on front cover

Benefits

Permanent binding method

100% recyclable

Factor to Consider

Side Sewn books do not lay as flat as perfect bound or Smyth sewn books.

Side Sewn

When a book is side-sewn, it means the text block consists of individual pages, as opposed to individual signatures. It’s also not a saddle-stitched book! The line of stitching is usually about 1/4” to 3/8” from the binding edge. We can extend the threads beyond the book so they are loose and we can run 2 or 3 lines of stitching for added uniqueness!

What’s the Appeal?

Side-sewn books stand out among other binding methods because the thread is visible on both the front and back covers. The vintage, stitched pattern of side-sewn books has also become very popular as a design element for projects. Also, the 100% cotton coloured thread is recyclable and can enhance the book’s design.

Benefits

- Exposed thread enhances the design

- Side-sewn books are very durable, much more than regular perfect binding

- There’s a huge selection of thread colours available on short notice

- Both coated and uncoated stocks can be used so there is more flexibility for stock choice

- Extra-thin books can be sewn with a zigzag pattern

- Side-sewing can be used to rescue perfect bound books that are falling apart

Things to Consider

- We sew 1/4” to 3/8” from the binding edge so extra space is required to ensure artwork and text are visible

- Side-sewn books do not open flat so the designer has to take this into account

- The grain direction of the stock must run parallel to the spine so this can affect the quantity of sheets required to complete a job

- The maximum thickness of the books is 3/4”