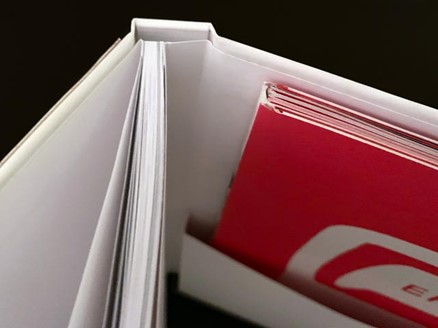

The production of these books as pictured requires one of our two automatic case makers. The book has been perfect bound before “casing in.” We had an additional score 3/4 of an inch on the back cover from the spine. We could not case it in on our casing in machine, the book is much thinner than the hard stiff spine. In this situation we took the finished perfect bound book, full surface glue the inside the front of the hardback case and then we formed a gusset pocket and glued it full surface, inside the back, cover of the case. We then inserted a product of red folder. When closed it looks like a hardback case bound book. It is reasonably durable functionable for something like this please call us.

Perfect Binding … with a Twist!

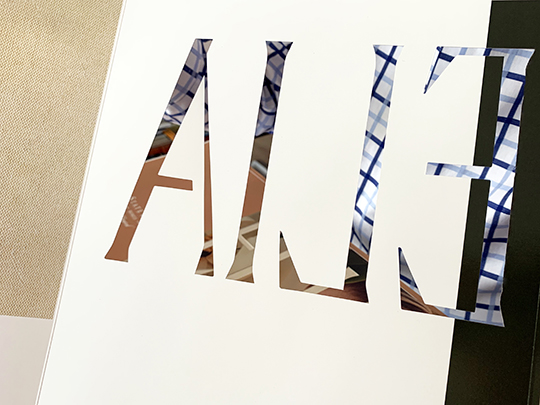

Think this week’s product is a basic perfect bound magazine? While we excel in perfect binding, we specialize in adding processes like die cutting and, in this case, pattern gluing.

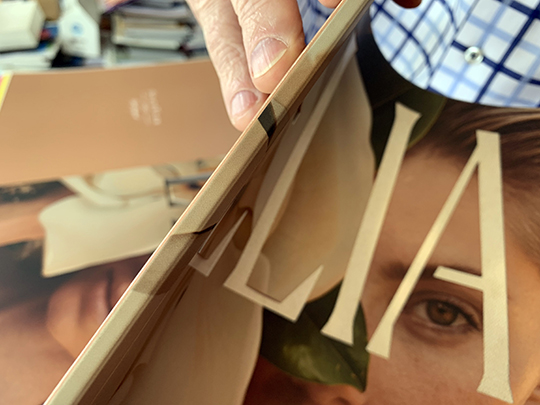

When you look closely at the cover of this book, you can see that the cover panel has the title die cut so the underlying printed middle panel shows through.

Normally, a double thick cover is simply full surface glued. That wasn’t an option for this job because the glue would squeeze through the die cut portion. We pattern glued the middle panel and then folded the die cut panel over, which ensures a close bond between the middle and cover panel without any glue residue showing.

In addition to regular perfect binding operations (section folding, perfect binding and 3-knife trimming), this job required die cutting, pattern gluing and hand folding of the cover.

When a perfect binding job–with a twist– comes across your desk, please give us a call!

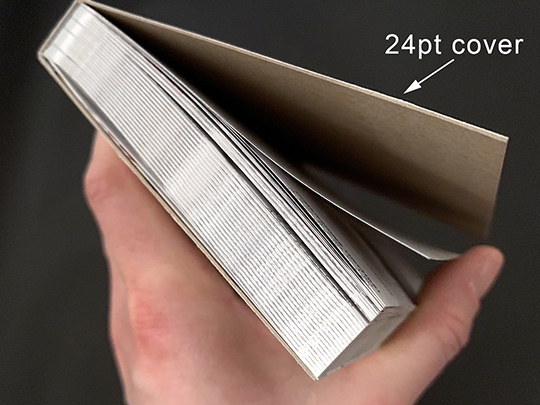

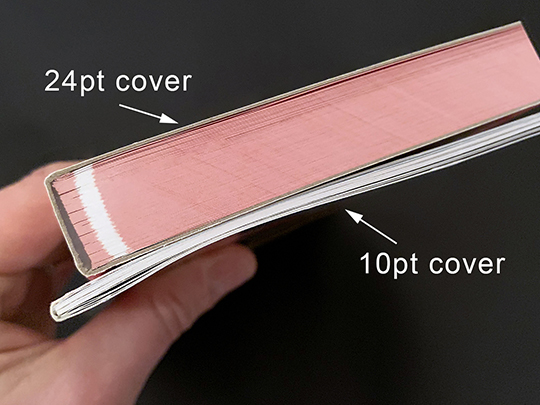

Our Latest Innovative Breakthrough: 24pt Cover Perfect Bound Books

The product I’m featuring this week is an example of how we are continuously innovating and improving upon book binding options.

Perfect binding has long been a common form of book binding, but it has some drawbacks – namely its limitations regarding cover thickness. Perfect bound books have been limited to a maximum cover thickness of 18pt … until now!

Our advancements have now made it possible for us to produce perfect bound books with 24pt covers! This opens up a world of possibilities for designers and printers that want to create durable books, without the cost of adding a hard, case bound cover.

Perfect bound books with 24pt covers can be intricately die cut, foil stamped and high die shaped (PMC die shaped).

With the developments we’ve made in perfect binding, there’s no telling what kinds of amazing book designs you’ll be seeing from us in the future!