Unlock Personalization Excellence with Ludlow Stamping for Your Hardback Books

In the dynamic world of bookbinding and finishing, the ability to personalize hardback books has taken center stage. Imagine having the names of personnel in various sizes, typefaces, and colors adorning your books—truly a bespoke touch. At our binding and finishing company, we bring a unique perspective to personalization, especially through a process called “Ludlow” stamping, a technique that has stood the test of time for over 150 years.

The Ludlow Stamping Advantage: When it comes to personalization, the Ludlow stamping technique offers unparalleled flexibility and precision. We can personalize hardback books with up to 3000 different names, each varying in size, font, and color. The Ludlow machine, a testament to craftsmanship, creates lead type for individual names like John Doe, ensuring a distinctive and elegant appearance on the book cover.

Seamless Foil Stamping: In our commitment to providing high-quality and cost-effective personalization options, we’ve seamlessly integrated Ludlow stamping into our processes. Unlike traditional methods that involve debossing or embossing impressions on the book cover, Ludlow stamping employs foil to create a sleek and refined appearance. This not only enhances the visual appeal but also allows us to offer a remarkable 80% cost savings on a per-unit basis for foil stamping on a run of 3000 names.

Quality Beyond Tradition: While Ludlow stamping is a 150-year-old process, our implementation ensures that the quality surpasses traditional standards. The precision and attention to detail in Ludlow stamping make each personalized name stand out with clarity and finesse. The result is a level of quality that not only pays homage to the rich history of Ludlow stamping but also meets the demands of modern aesthetics.

Cost-Effective Personalization: Choosing Ludlow stamping for personalized, individual names on the front of your hardback book not only ensures top-notch quality but also provides a cost-effective solution. The substantial reduction in per-unit pricing for a run of 3000 names makes Ludlow stamping an attractive choice for publishers and authors seeking both excellence and efficiency.

How to Get Started: If you’re intrigued by the prospect of having personalized, individual names stamped on the front of your hardback books, we invite you to give us a call. Our dedicated team is ready to discuss your specific requirements and showcase the capabilities of Ludlow stamping. Additionally, feel free to email us for a sample, allowing you to experience firsthand the elegance and uniqueness that Ludlow stamping brings to personalized book covers.

Elevate the personalization of your hardback books with Ludlow stamping, a time-honored technique that seamlessly blends tradition with modern efficiency. Experience the unmatched quality, flexibility, and cost-effectiveness of Ludlow stamping by reaching out to us today. Transform your hardback books into personalized masterpieces that leave a lasting impression on readers and make your literary works truly stand out.

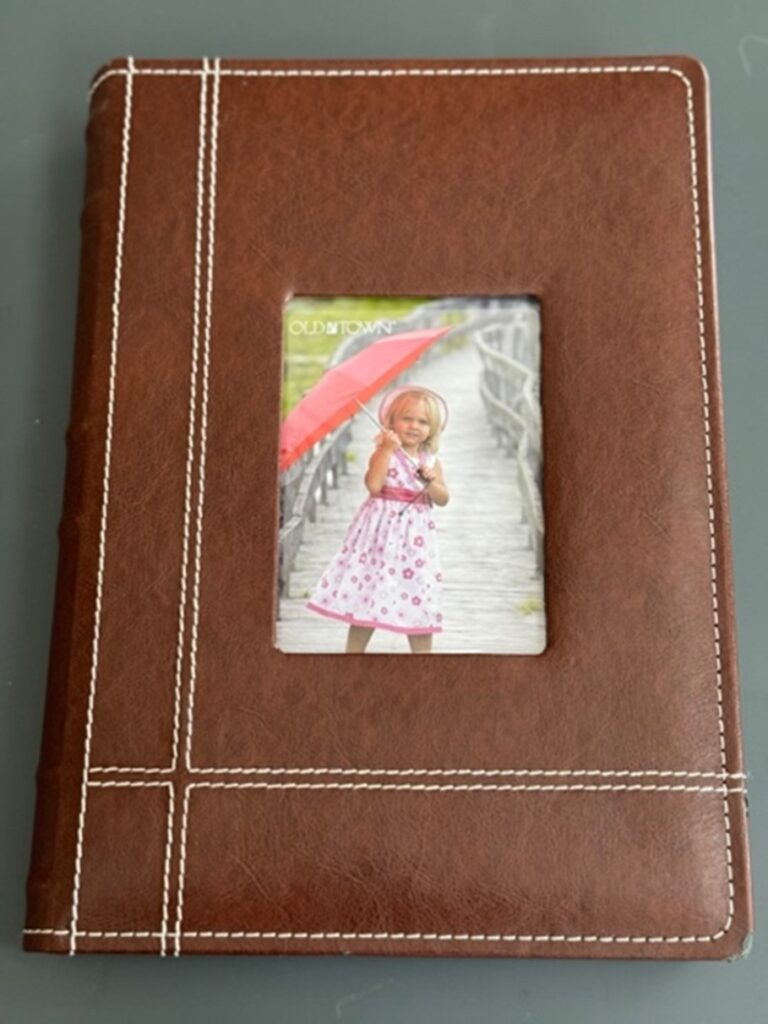

These five pictures indicated have five distinctive. Firstly, is the hub spine, which is purely decorative. Originally the “hub spine” were part of the binding process but now they are purity decorative. Secondly, the extensive detailed edge sewing. Thirdly, the pocket on the inside front cover. You can slide something in and out and then you see the front cover. The picture that’s been slid in it could be any kind of a picture. The cover has to be four sided wrapped, which is on the “die cut window”, which is incredibly expensive. We have an alternative to that method and the alternative is that we simply wrap the cover in the normal matter in this situation it’s brown. We die cut the window in the front of the case that then exposes gray board but we then do is put a sheet inside the cover we take a 25 point chip sheet that is die cut the very same as this window, same sheet size as the overall book and then we spray paint the inside of that hole the same colour brown. Our cost difference versus the one illustrated here where the front wrap cover has to be die-cut with a flap and the hand wrapped inside versus our method of putting a die-cut sheet in the front and spray painting the inside. The cost difference in our operation is 20 times greater for the picture shown here versus our method in addition to the binding of the normal book.