What are bevelled edges? (U.S. spelling is “Beveled”). We bevell the edges of case bound books or ring binders.

What is highly distinctive about these three particular products other than the incredibly large size is the fact that the top, face and foot of the covers have been “bevelled” or angled cut. You can see from the pictures. Sometimes, we work with board which is up to 200pt thick. The board of a normal hardback case bound book is usually 100pt. Sometimes these covers are 150pt or 200pt. The bevelled edge is usually the angle as you can see here, but it could be more angled. As you can see, it’s wrapped like a normal hardback case bound book and stamped as normal. The black one has been bound with Chicago screws which are removable. You’ll notice a different “bevelling” on the one book and the corners are square. On the unbelievably large, black book the bevelled corners are rounded. This cover is obviously deeply debossed and multiple applied cover colours in the front. The green, oversize book which is bevelled on all three sides, front and back cover as a printed and end paper has sewn a clear overlay sheet inside the end paper. Again, another unusual application.

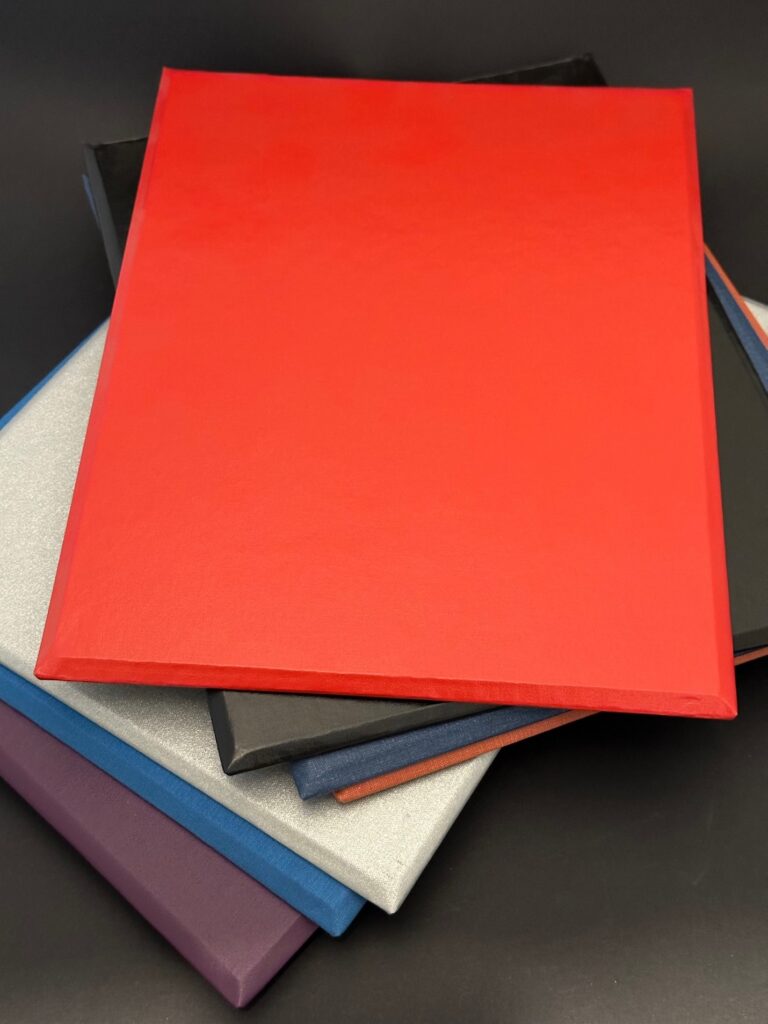

Here is yet again of some pictures of hardback books which have been “bevelled” on the edges. The red on top board is a 200pt. The bottom two boards are much thinner; 150pt board. They can be the covers of hardback case bound book with a square corner or rounded a different radii. We can actually produce different angles 45° or 35° depending how much slant image your client wants. Yes, this “decorated” – style is not very common, but if your client needs it, please give us a call.

these pictures are as good as a thousand words! Bevelling is only effective on an unusually thick cover. The commonest thickness for the cover of a case bound book is 100 point. These pictures are all 200 or 200+ point thickness of covers.

In the overall cost of producing a hard-back book or a case wrapped ring binder the cost of the “board” is minimal. For job requiring “bevelling” we mount (full surface glue 2 or 3, 100-point boards together). The boards are then bevelled on three sides (I’ve never seen a job requiring only one or two sides).

Features:

- Angled (45) edge

- Smooth

- Book is heavy

Benefits:

- Greatly differentiate product (book or ring binder)

- So UNUSUAL so therefore “VERY” memorable

Factor to consider:

- Extra thick

- Heavy covers will probably affect mailing cost

TIPS FOR REDUCING PROMBLEMS IN THE BINDERY

Always assemble a full-scale mock-up of any packaging/dimensional project

How does the design work at the folds and seams? Where does the legal copy sit? After all that, does it fit in the needed shipping containers and the commercial display cases and shelves?