Unveiling Artistry: The Four Distinctive Features of an Exposed Smyth Sewn Book

In the world of bookbinding, the exposed Smyth sewn book stands out as a testament to craftsmanship, innovation, and attention to detail. This unique creation is not just a book; it’s a work of art meticulously produced through a multi-step process. In this article, we will explore the four exceptional characteristics that make an exposed Smyth sewn book an extraordinary masterpiece.

Shaped Face: Crafting Uniqueness with Die/PMC Machines

The journey of an exposed Smyth sewn book begins with a distinctive face shape. Achieved through one of our three high die/PMC machines, this feature adds a level of uniqueness that captivates the reader from the first glance. The precision and versatility of our machines ensure that each book receives a face shape tailored to perfection, setting it apart in a sea of conventional designs.

Seamless Binding with Side Sewers: Bringing Covers to Life

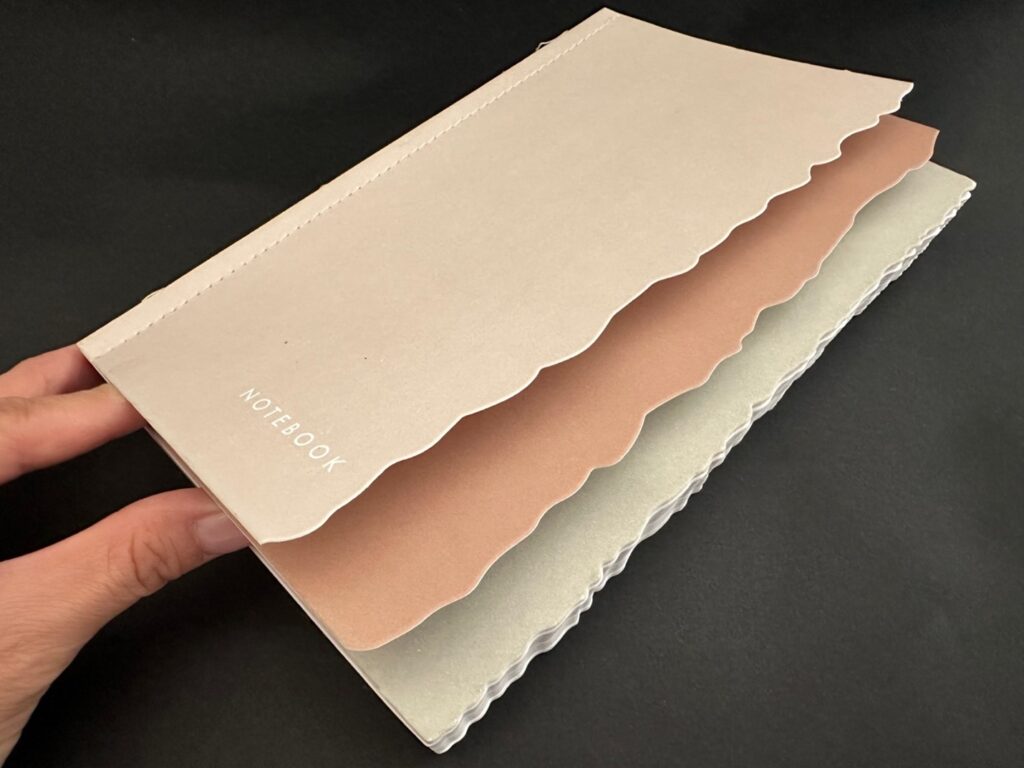

The integration of three shaped cover sheets is a key aspect that sets the exposed Smyth sewn book apart. Our two side sewers play a crucial role in seamlessly stitching these cover sheets together. This meticulous process not only ensures durability but also enhances the overall aesthetic appeal of the book. The result is a visually stunning and structurally robust cover that captivates both the eye and the touch.

Die-Cut Precision with Automatic Die Cutters

The top three heavy 12-point sheets of an exposed Smyth sewn book undergo a transformational process on one of our six automatic die cutters. This step adds a layer of precision and intricacy to the book’s design, creating visually appealing shapes and patterns. The die-cut sheets contribute to the overall tactile and visual experience, making each page a canvas of artistry.

Full Surface Gluing: Elevating Elegance and Durability

The final touch in the creation of an exposed Smyth sewn book involves the application of full-surface glue to the top three sheets. This process ensures a secure and seamless bond with the top page of the sewn book, enhancing both elegance and durability. The result is a book that not only looks exquisite but is built to withstand the test of time, offering readers a lasting and enjoyable reading experience.

An exposed Smyth sewn book is a celebration of ingenuity and craftsmanship. The combination of a shaped face, meticulously sewn covers, precision die-cutting, and full-surface gluing results in a book that goes beyond the ordinary. As the creators behind this extraordinary process, we take pride in delivering books that are not just read but experienced. Whether you are a publisher, an author, or a book enthusiast, embracing the uniqueness of an exposed Smyth sewn book is an invitation to appreciate the artistry that goes into each page, cover, and binding. Join us in redefining the boundaries of bookbinding and discover the world of exposed Smyth sewn books – where every detail tells a story of craftsmanship and creativity.

These five pictures show a distinctive method of binding a book. The pages are not three knife trimmed as we would do for any book that was going to be hardback case bound. In this situation, instead of making a one piece cover we ran two separate covers front and back, through 1 of our 2 high-speed, automatic case makers. We then glue mount full surface, front and back cover to the book block and the book is trimmed. Before the covers is applied, the cover is wrapped, but it’s meant to be flush at the head, foot and face. When the book is closed as you can see the smyth sewing thread is exposed. This is just as durable as a normal hardback case bound book. In our situation somewhat more expensive than a normal one-piece cover, hardback case bound book, but if you want something it’s just as durable and quite distinctive like this, please call us.

These five pictures show an unusual binding style of a case style cover. In this situation, the book block is exposed. The green case was produced on one of our two automatic case makers. What’s different from the normal hardback case bound product is the brown liner paper has been fully applied to the case on the book. The book block has been full surface glued to the outside back cover, as you can see how the book lies flat. The cover in the one picture falls off the spine in the front. Yes, the folding, collating, smyth sewing and three knife trimming is the same. The cost of manufacturing of the green cases is the same, but where the difference comes in is, it got to go through the case making machine a second time to apply the beige cover and then the casing in process is much slower because the machine must be geared and adapted so it doesn’t glue the front cover to page one.