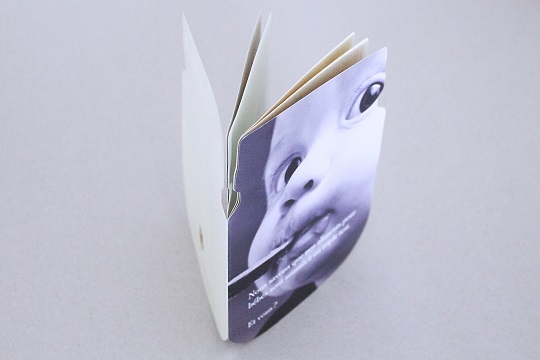

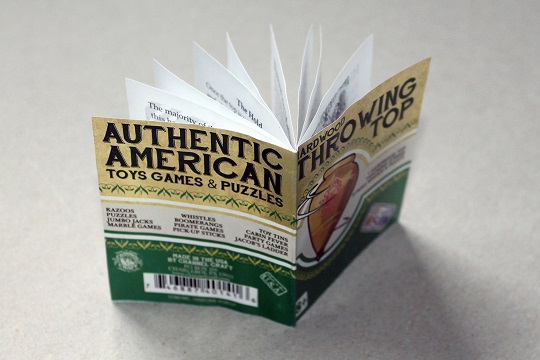

What is paste binding? It is a booklet that appears to be wire saddle stitched, but there are no wire stitches (staples). Rather than using wire stitches, the folded pages are held together with glue. Paste bound “booklets” are produced on a conventional “buckle” folding machine.

In the late 1950’s, automatic saddle stitchers were introduced which cut the cost of producing saddle stitched books by about 90%! Prior to this saddle stitched books were hand fed on a wire stitching machine & then manually trimmed on a cutting machine. Prior to the 1950’s, “paste binding” was quite common. Most binderies did “paste binding”. Paste binding has limitations compared to wire saddle stitching.

Features

- Glue on every page at the spine

- The spine lays flatter that wire saddle stitching

Benefits

- Sometimes much cheaper than saddle stitching

- We can P.M.C. (HIGH DIE) shape paste bound booklet. When saddle stitched books are squeezed through the P.M.C. machine the stitches pop out!

- When the booklet is being paste bound all in one pass, additional operations such a final soft fold and/or “clip” seals can be added on 1 or 2 or 3 sides all in one pass!

Limitations

- Narrower range of stocks

- Depending on booklet size booklets can only be a maximum of 32 pages

- Glued booklets cannot have a separate cover

- Stocks cannot be mixed

Factors to consider

- There are a number of physical limitations

- We are one of the very few binderies can now do this process

- Most suitable for long runs